- Shanghai Zhongshen International Trade Co., Ltd. - Two decades of trade agency expertise.

- Service Hotline: 139 1787 2118

Want to gain a competitive edge in European and American markets? Has your electromechanical product passed strict electromagnetic compatibility (EMC) testing? As a key project, how to ensure compliance with radiation disturbance testing and reduce risks caused by measurement uncertainty?

Electromagnetic Compatibility (EMC)As one of the commonly used non-tariff technical barriers in European and American markets, it usually appears in the form of technical regulations, standards, and conformity assessment procedures. Related productsimport and exportEnterprises should highly prioritize the electromagnetic compatibility requirements of products, ensuring compliance with international market access standards in key testing projects like radiation and conduction.

Electromagnetic compatibility issues of electromechanical products

The widespread use of electromechanical products has led to electromagnetic compatibility issues. Since electromagnetic waves are invisible, electromagnetic compatibility issues are often overlooked. Electromagnetic compatibility includes two aspects: disturbance and immunity. Disturbance refers to the electromagnetic interference generated by products during normal operation not exceeding specified limits; immunity refers to the ability of products to operate normally in electromagnetic interference environments.

Radiation disturbance is a key project in electromagnetic compatibility testing. The testing requirements for this project include: arranging and setting up the test site according to standard regulations (e.g., testing in an anechoic chamber or shielded room), the test site must be calibrated, parameters like site attenuation or background noise must meet standard requirements, and the equipment under test and auxiliary equipment should maintain an appropriate distance. These subjective and objective uncertain factors result in measurement uncertainty in radiation disturbance test results.

Definition of Measurement Uncertainty

Measurement uncertainty is a parameter associated with the measurement result, serving as an indicator of the dispersion of the measured value.

Sources of Measurement Uncertainty

Considering factors affecting measurement results, measurement uncertainty primarily originates from the following aspects:

(1) Measured Object

Factors related to the measured object include:

(1) Incomplete definition of the measurand.

(2) Imperfect method for realizing the definition of the measurand.

(3) Measurement samples not fully representing the defined measurand.

(4) Poor stability of the measurand.

(2) Measurement Equipment

Uncertainty introduced by measurement equipment stems from:

(1) Status of measurement standards, instruments, and their accessories.

(2) Calibration uncertainty of measurement standards and instruments.

(3) Maximum permissible error or accuracy class of measuring instruments.

(3) Measurement Environment

Uncertainty caused by environmental factors may originate from:

(1) Temperature variations, vibration noise, power supply fluctuations.

(2) Air composition, contamination, flow conditions, atmospheric pressure, thermal radiation, etc.

(4) Measurement Personnel

Uncertainty from measurement personnel mainly includes: reading errors, aiming errors, operational errors, etc.

(5) Measurement Method

Sources of uncertainty in measurement methods include:

(1) Errors in measurement principles.

(2) Process errors.

(3) Data processing methods, etc.

Evaluation of Radiated Disturbance Uncertainty

According to standard GB 9254.1-2021, conduct radiated disturbance testing on standard signal sources. Evaluate radiated disturbance measurement uncertainty based on JJF 1059.1-2012, CNAS-GL07:2015, CNAS-GL007:2020, and GB/T 6113.402-2018.

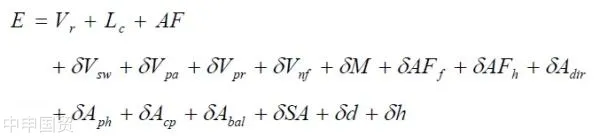

(1) Establishing Measurement Model

First, establish a measurement model for radiated disturbance uncertainty, identifying all parameters and conditions requiring evaluation.

(2) Evaluation of Type A Uncertainty

Type A uncertainty evaluation involves calculating standard uncertainty through statistical analysis of a series of observed values. The experimental standard deviation calculated using the Bessel formula represents Type A uncertainty. By measuring quasi-peak detection, horizontal polarization direction, and disturbance values at two frequencies (50MHz and 500MHz), the dispersion of the measurement system was evaluated. Results show that at 50MHz, the average value was 50.13 dBμV; at 500MHz, the average value was 65.58 dBμV. The calculated Type A standard uncertainty for laboratory radiation disturbance is: u(x)=0.15dB.

(3) Evaluation of Type B Uncertainty

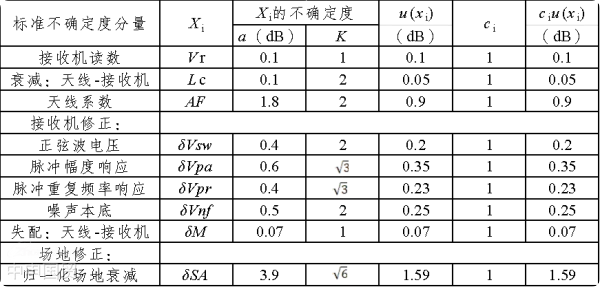

Type B uncertainty evaluation is primarily based on the following sources:

(1) Previous measurement data.

(2) Experience regarding the characteristics and performance of materials and instruments.

(3) Manufacturing instructions or technical documents provided by production departments.

(4) Data from verification certificates or calibration certificates.

(5) Reference data from manuals, etc.

Based on actual conditions, the calculated Type B uncertainty is 1.91dB.

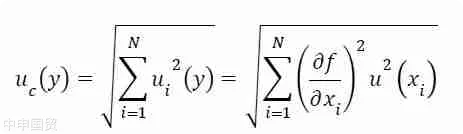

(4) Calculation of Combined Uncertainty and Expanded Uncertainty

Assuming all input quantities are independent of each other, the combined standard uncertainty uc(y)=2.06dB. In industrial and commercial applications, the combined standard uncertainty needs to be multiplied by a coverage factor k to calculate the expanded uncertainty. With a 95% confidence level, k=2, and the expanded uncertainty u=2×uc(y)=2×2.06=4.12dB. Thus, the expanded uncertainty for radiation disturbance is 4.12dB.

Recommendations for Relevant Import and Export Enterprises

Radiation disturbance is a critical item in electromagnetic compatibility (EMC) testing, and its compliance is closely related to the results of other test items. Measurement uncertainty reflects the dispersion of measurement results and significantly impacts the final determination of EMC test conclusions.

Therefore, relevant import and export enterprises of electromechanical products are advised to:

(1) Fully understand EMC testing requirements and prioritize radiation disturbance testing.

(2) Continuously monitor testing standards, test items, and market access conditions.

(3) Stay updated on feedback and changes in policies and standards in domestic and international markets, adjusting products and strategies accordingly.

EMC compliance is a mandatory requirement for international market access. Qualified test results will open doors for your products in global markets. By understanding and adhering to the latest EMC testing standards, you can enhance product compliance and market competitiveness, helping your company stand out on the global stage!

Related Recommendations

Category case

Contact Us

Email: service@sh-zhongshen.com

Related Recommendations

Contact via WeChat

? 2025. All Rights Reserved. Shanghai ICP No. 2023007705-2  PSB Record: Shanghai No.31011502009912

PSB Record: Shanghai No.31011502009912